Views: 0 Author: Site Editor Publish Time: 2025-09-20 Origin: Site

In the world of industrial infrastructure, change often comes slowly. For decades, the backbone of fluid and gas transport has been built upon traditional materials: steel, concrete, cast iron. These materials are trusted, familiar, and have served their purpose. However, in an era defined by efficiency, sustainability, and smart economics, a quiet revolution is underway. A growing number of forward-thinking companies across the oil and gas, chemical, mining, and water management sectors are making a decisive switch to Reinforced Thermoplastic Pipes (RTP).

At Anhui United Pipeline Co., Ltd., we are at the forefront of this revolution, manufacturing high-grade RTP that is redefining industry standards. But what is driving this mass migration away from conventional pipes? The shift isn't based on a single factor, but rather a powerful convergence of performance, economic, and environmental advantages that make RTP the intelligent choice for the 21st century.

1. The Fundamental Weakness of Traditional Pipes

To understand the rise of RTP, we must first acknowledge the inherent challenges posed by traditional piping systems:

Corrosion: The Ever-Present Enemy: Steel and cast iron pipes are highly susceptible to corrosion, both internally from conveyed fluids and externally from soil and moisture. This degradation leads to leaks, product loss, environmental contamination, and necessitates expensive cathodic protection systems and constant monitoring.

Weight and Logistical Nightmares: Traditional pipes are incredibly heavy. Transporting them requires heavy machinery and a significant number of trucks. Installation is a labor-intensive process involving large crews, heavy welding equipment, and precise alignment. This translates to high fuel costs, extended project timelines, and substantial installation expenses.

Limited Flexibility: Rigid pipes cannot be easily bent or maneuvered around obstacles. They require a multitude of elbows, joints, and fittings, each representing a potential future leak point. Terrain shifts, seismic activity, and frost heave can cause stress fractures and joint failures in rigid systems.

High Maintenance and Short Lifespan: The constant battle against corrosion and the mechanical stress on joints mean traditional systems have a relatively shorter operational lifespan and require frequent, costly maintenance and inspections.

2. What is RTP? A Marvel of Modern Engineering

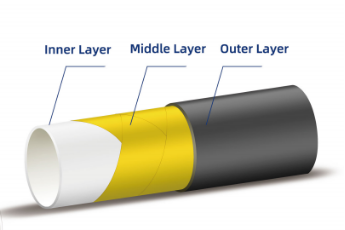

Reinforced Thermoplastic Pipe (RTP) is a composite pipe designed to overcome these exact challenges. Our RTP at Anhui United Pipeline is typically constructed in three layers:

Inner Layer(Media Transmission Layer): Materials primarily include PE100, PE-RT ll, PE-X, PA, PVDF, etc.

Middle Layer(Reinforcement Layer): Materials mainly consist of glass fiber, aramid fiber, polyester fiber, steelwire (rope), etc.

Outer Layer(Protective Layer): Typically HDPE or PE-RT ll. Anti-ultraviolet (Uv) stabilizers and antioxidants canbe added to the protective layer outside the RTP pipeline laid on the surface.

This composite structure is where the magic happens, delivering a product that is simultaneously stronger, lighter, and more durable than its traditional counterparts.

3. The Compelling Reasons for the Switch to RTP

A. Unmatched Corrosion Resistance

This is arguably the single biggest driver. The inner layer is inert to a vast array of corrosive agents, including saltwater, acids, alkalis, and hydrocarbons. This eliminates internal corrosion, dramatically reducing the risk of leaks and failures. There is no need for expensive corrosion inhibitors, coatings, or cathodic protection systems. The result is a longer-lasting asset and a significantly safer operation, particularly crucial for environmentally sensitive areas.

B. Dramatically Reduced Lifecycle Cost

While the initial material cost of RTP can be comparable to coated steel, the true savings are realized over the entire lifecycle of the pipeline:

Installation Savings: RTP is supplied in long lengths on reels, this means installation is incredibly fast. A small crew with a standard winch or laying device can install kilometers of pipe per day, compared to weeks for welding and laying traditional pipe. Fewer joints mean fewer potential leak points and lower labor costs.

Maintenance Savings: The corrosion-resistant nature of RTP means it requires minimal maintenance. There are no coatings to repair or cathodic systems to monitor. Inspection costs are lower, and the predictable lifespan simplifies budgeting.

Operational Efficiency: The smooth inner surface of RTP offers a lower friction coefficient than steel, reducing pumping energy requirements and costs over the pipeline's lifetime.

C. Superior Strength-to-Weight Ratio and Flexibility

RTP is remarkably lightweight—This slashes transportation costs, allows for easier handling in remote or difficult-to-access terrain, and reduces the carbon footprint of logistics.

Its flexibility is a game-changer. RTP can be bent to a much smaller radius than rigid pipe, allowing it to snake around obstacles and conform to the natural contours of the landscape. This flexibility also makes it highly resistant to ground movement, frost heave, and seismic events, as it can absorb stress and strain without fracturing.

D. Enhanced Safety and Environmental Protection

The composite structure of RTP is inherently leak-resistant. In the unlikely event of damage, the failure mode is typically a slow weep rather than a catastrophic, high-energy rupture common in steel pipelines. This greatly enhances onsite safety for personnel. Furthermore, the superior corrosion resistance directly translates to a massively reduced risk of product leakage into the surrounding environment, protecting soil and groundwater—a critical consideration for any responsible company.

E. Longevity and Reliability

A well-manufactured RTP system is designed for a long service life, often exceeding 50 years with minimal degradation. This provides companies with a stable, reliable, and predictable infrastructure asset.

4. Applications Driving Adoption

The industries switching to RTP are diverse:

Oil & Gas: Used for gathering lines, flow lines, water injection lines, and gas distribution, especially in corrosive offshore and onshore environments.

Chemical Processing: For transporting aggressive acids, alkalis, and solvents within plant boundaries.

Mining: For tailings and slurry transport, dewatering operations, and leaching processes where abrasion and corrosion are major issues.

Water & Wastewater: For outfall lines, brine disposal, and water intake systems where corrosion resistance is key.

Conclusion: The Future is Flexible

The trend is clear. The switch from traditional pipes to Reinforced Thermoplastic Pipe is not a fleeting fad; it is a rational, economic, and environmental evolution. Companies are recognizing that to build resilient, cost-effective, and sustainable operations, they must embrace innovative materials that offer superior performance.

At Anhui United Pipeline Co., Ltd., we are proud to empower this transition. Our commitment to rigorous quality control, advanced manufacturing techniques, and international standards ensures that our RTP products deliver on the promise of a safer, more efficient, and more profitable pipeline solution.

Contact Anhui United Pipeline Co., Ltd. today to discuss how our RTP solutions can future-proof your pipeline infrastructure.