Views: 0 Author: Site Editor Publish Time: 2025-10-28 Origin: Site

Have you ever wondered how the strength of multi-layered materials can be affected by the time between layers? In the world of Resin Transfer Molding (RTP), interlayer bonding is crucial to the performance of composite structures.

In this article, we'll explore the importance of interlayer bonding in RTP design. We'll discuss how stress distribution and bonding strength play key roles in ensuring the durability of materials like reinforced thermoplastic pipes (RTP). You'll learn how to improve these aspects for better performance and reliability.

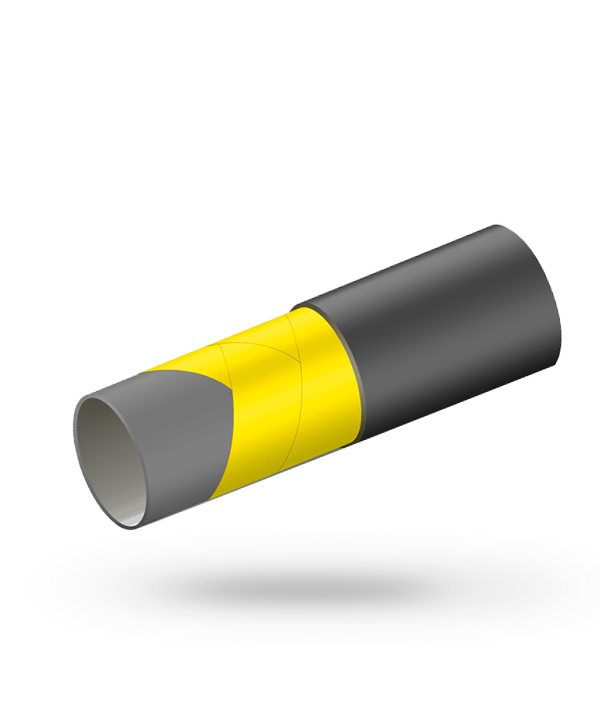

Resin Transfer Molding (RTP) is a widely used process in the manufacture of composite materials. It involves injecting resin into a mold containing dry reinforcement material, typically fibers such as glass, carbon, or aramid. This process allows for the creation of lightweight, strong, and durable components, making it ideal for industries such as aerospace, automotive, and construction. RTP's flexibility in design and ability to create complex geometries make it increasingly popular in the production of reinforced thermoplastic pipes (RTP), which combine the strength of metal with the lightweight characteristics of plastic.

In recent years, RTP technology has expanded into additive manufacturing, particularly in 3D printing. The importance of interlayer bonding in these applications cannot be overstated, as it directly impacts the overall mechanical performance and durability of the finished product.

In RTP design, maintaining a strong interlayer bond is crucial for the structural integrity of multi-layered components. However, during long print intervals, the bond strength between consecutive layers can deteriorate, leading to potential failures. This issue is especially significant in large-scale applications such as reinforced thermoplastic pipes, where the reliability and consistency of the structure are paramount. Understanding how interlayer bonding affects stress distribution and failure mechanisms in these components is key to improving RTP design.

Interlayer bonding plays a pivotal role in the mechanical performance of RTP structures. In composite materials, the bond between layers ensures that the entire structure behaves as a unified entity rather than separate parts. Poor interlayer adhesion can lead to weak points in the structure, where stress concentration occurs, causing premature failure. For example, in reinforced thermoplastic pipes, weak interlayer bonding could lead to cracks or delamination under pressure, significantly reducing the lifespan of the pipe.

Research has shown that the time interval between layers in RTP processes significantly impacts the strength of interlayer bonds. Longer intervals between layer deposition can result in a reduction of bond strength, as the material may begin to cure or dry before the next layer is applied. This leads to an increase in porosity and voids at the interface, weakening the adhesion. In the case of reinforced thermoplastic pipes, the reduction in interlayer strength can directly affect the load-bearing capacity and overall durability of the product.

To ensure strong interlayer bonds, it is essential to control the time interval between layer deposition. Keeping the intervals short and consistent is key. Additionally, optimizing curing times and environmental conditions such as temperature and humidity can help improve bonding strength. Using additives in the resin mix, such as bonding agents or plasticizers, can also enhance interlayer adhesion, ensuring better performance in applications like reinforced thermoplastic pipes.

In multilayered RTP structures, stress is distributed across the layers based on their material properties and bonding strength. When a load is applied, the layers should work together to distribute the stress evenly. However, weak interlayer bonding can cause localized stress concentrations, which may lead to cracking or delamination. For example, in reinforced thermoplastic pipes, inadequate stress distribution due to poor bonding could result in pipe failure under high-pressure conditions.

The thickness of individual layers in RTP designs plays a crucial role in stress distribution. Thicker layers can absorb more stress but may also contribute to higher internal stress if the bonding between them is not uniform. Research suggests that variations in layer thickness can cause uneven stress distribution, leading to potential weak points. In the case of reinforced thermoplastic pipes, varying the layer thickness may affect the pipe's ability to withstand internal pressure, necessitating careful design considerations.

Finite Element Modeling (FEM) is an essential tool for simulating stress distribution in RTP components. By creating a digital model of the multi-layered structure, engineers can predict how stress will behave under various load conditions. FEM simulations help identify weak spots in the design, allowing for adjustments before physical testing. This technique is invaluable in designing reinforced thermoplastic pipes, where precise stress management is crucial for the pipe's structural integrity.

The material properties of the resin used in RTP processes have a direct impact on interlayer adhesion. The composition of the resin, its viscosity, curing rate, and chemical additives all influence how well the layers bond. In the case of reinforced thermoplastic pipes, the resin used must be compatible with the reinforcement material, whether it's glass fibers, carbon fibers, or others. The quality and consistency of the resin mixture are crucial for ensuring strong, durable interlayer bonds.

Environmental factors such as temperature, humidity, and air quality can influence the adhesion between layers in RTP processes. Additionally, the printing speed and pressure used during the deposition process also play a significant role in bonding strength. For reinforced thermoplastic pipes, controlling these variables ensures that each layer bonds effectively to the next, preventing the formation of weak spots or voids.

To optimize interlayer adhesion in RTP designs, it is essential to control both the material composition and environmental conditions during the printing process. This includes adjusting the resin properties, ensuring consistent printing speeds, and maintaining ideal temperature and humidity levels. Furthermore, employing strategies such as pre-heating layers or using bonding agents can help improve the overall bond strength, ensuring durability in applications like reinforced thermoplastic pipes.

Extended time intervals between layers can lead to layer delamination, where the bond between two consecutive layers weakens or fails entirely. This delamination is often caused by the formation of voids or cracks at the interface between layers. In reinforced thermoplastic pipes, delamination can compromise the pipe's ability to withstand pressure, leading to failure under load.

Digital Image Correlation (DIC) and Scanning Electron Microscopy (SEM) are powerful tools used to analyze the failure points in RTP structures. These methods allow for detailed examination of the interlayer regions, helping identify cracks, voids, and other weaknesses. In the case of reinforced thermoplastic pipes, these techniques can pinpoint where delamination or stress concentration occurs, providing insights into how to improve the design.

Several studies have examined the cracking behavior of RTP components with long time intervals between layers. These studies have shown that cracks tend to propagate through the weakest interlayer bonds, often starting from the points with the highest stress concentration. In reinforced thermoplastic pipes, this means that the design must account for potential failure modes, such as the development of cracks in the interlayer regions.

FEM modeling is crucial for predicting the behavior of RTP structures under stress. By simulating the interlayer bonding and stress distribution, engineers can identify potential failure points before physical testing. In reinforced thermoplastic pipes, FEM can help optimize the design by predicting how stress is distributed across the layers and ensuring that the interlayer bond is strong enough to handle the expected loads.

Cohesion between layers is a critical factor in the overall structural integrity of RTP designs. The stronger the cohesion, the better the stress is distributed across the layers. FEM models can simulate different cohesion scenarios to predict the behavior of the structure under various conditions. In reinforced thermoplastic pipes, understanding cohesion is key to ensuring that the pipe can handle high-pressure environments without failure.

One of the most effective ways to improve interlayer bonding is through material modification. Adding bonding agents, plasticizers, or fillers to the resin can significantly improve the bond strength between layers. In reinforced thermoplastic pipes, these additives can help enhance the material's ability to withstand stress and prevent failure under high-pressure conditions.

By optimizing the design of the RTP structure, engineers can minimize stress concentrations at weak points. For reinforced thermoplastic pipes, this may involve adjusting the layer thickness, reinforcing certain areas of the pipe, or altering the geometry to ensure even stress distribution. These adjustments can help prevent premature failure and extend the lifespan of the pipes.

Carefully controlling the layer deposition process and curing time is essential for ensuring strong interlayer bonds. By maintaining consistent printing speeds, temperatures, and humidity levels, the likelihood of weak bonds and cracks can be minimized. For reinforced thermoplastic pipes, following best practices during printing and curing can improve overall structural performance and durability.

| Topic | Description |

|---|---|

| Interlayer Bonding in RTP | The adhesion between consecutive layers of resin and reinforcement material in RTP designs. |

| Impact of Poor Bonding | Weak interlayer bonding leads to stress concentrations, cracks, and reduced durability in RTP. |

| Importance of Stress Distribution | Even stress distribution prevents weak spots and ensures better load-bearing in RTP structures. |

| Improving Bonding | Optimizing resin properties, controlling environmental factors, and using bonding agents. |

| Factors Affecting Stress | Material properties, layer thickness, and interlayer bonding influence stress distribution in RTP. |

| FEM Modeling for RTP | FEM modeling helps predict stress distribution and failure points, improving design efficiency. |

| Benefits of Reinforced RTP | Reinforced thermoplastic pipes combine strength, flexibility, and durability for high-pressure use. |

| Time Intervals Between Layers | Longer time intervals can weaken bonding, reducing RTP strength and performance. |

The relationship between interlayer bonding and stress distribution is crucial for RTP designs. Poor bonding leads to stress concentrations and early failure, especially in reinforced thermoplastic pipes. Optimizing material properties, controlling environmental factors, and using advanced modeling techniques can enhance RTP durability and performance. Future RTP designs should focus on improving interlayer bonding and stress distribution. By refining materials, printing processes, and simulation techniques, companies like Anhui United Pipeline can deliver high-performance reinforced thermoplastic pipes that offer long-term reliability and strength.

For reinforced thermoplastic pipes, maintaining strong interlayer bonding is essential to ensure the long-term durability and performance of the pipe under high-pressure conditions.

A: Interlayer bonding in RTP design refers to the adhesion between consecutive layers of resin and reinforcement material. It is crucial for the structural integrity and strength of the final product, such as reinforced thermoplastic pipes (RTP).

A: Poor interlayer bonding leads to stress concentrations, cracks, and delamination, especially in reinforced thermoplastic pipes. This reduces the overall durability and mechanical performance of RTP designs.

A: Stress distribution ensures that the load is evenly spread across the RTP structure. Without it, weak spots can form, leading to premature failure, particularly in multi-layered structures like reinforced thermoplastic pipes.

A: Improving interlayer bonding involves optimizing resin properties, controlling environmental factors, and using advanced bonding agents. This ensures stronger, more durable RTP structures.

A: Material properties, layer thickness, and interlayer bonding significantly influence stress distribution in RTP designs. Ensuring uniform bonding helps prevent localized stress points that could cause failure.

A: Yes, FEM modeling allows for accurate simulations of stress distribution and failure points in RTP designs. It helps engineers identify potential weak spots before physical testing.

A: Reinforced thermoplastic pipes offer strength and durability while maintaining flexibility and lightweight characteristics. They are ideal for high-pressure applications, thanks to their excellent interlayer bonding and stress distribution.

A: Longer time intervals between layers can weaken interlayer bonding, leading to reduced stress distribution and mechanical strength. Keeping intervals short ensures better adhesion and performance in RTP designs.