Views: 0 Author: Site Editor Publish Time: 2025-12-30 Origin: Site

Reinforced Thermoplastic Pipes (RTP) are revolutionizing fluid transport in agriculture and industry. These advanced pipes offer unmatched durability, corrosion resistance, and efficiency for transporting water, fertilizers, chemicals, and oils.

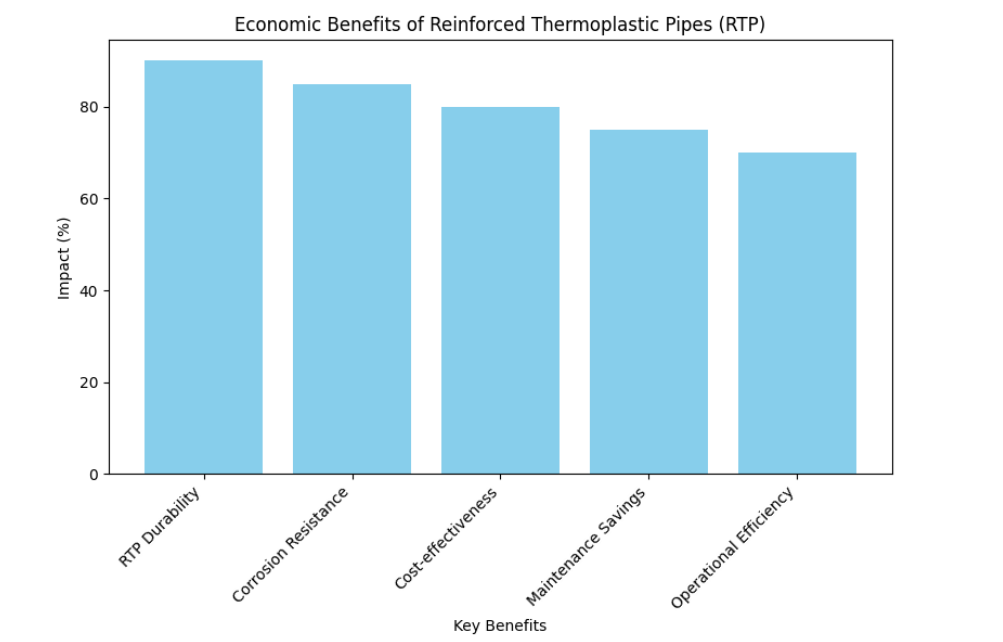

In this article, we’ll explore the economic benefits of RTP in both agricultural and industrial fluid systems. You’ll learn how RTP reduces costs, enhances system longevity, and boosts operational efficiency across sectors.

Agriculture relies heavily on efficient fluid transport systems, especially for irrigation and fertilizer application. As water scarcity becomes a global issue, farmers are seeking solutions that not only reduce water waste but also ensure the durability of their piping systems. RTP pipes, with their superior resistance to corrosion and wear, provide a long-term solution for these systems.

RTP’s ability to withstand high-pressure environments makes it an ideal choice for large-scale irrigation systems, where pressure fluctuations can cause damage to traditional piping materials like PVC and steel. With RTP, farmers can expect fewer leaks, less downtime, and significant cost savings over time.

In industrial sectors, fluid transport systems are essential for chemical processes, food manufacturing, and oil & gas operations. Industrial pipes are subjected to constant pressure and exposure to harsh chemicals, which can quickly deteriorate traditional piping materials. RTP's reinforced structure ensures its durability and longevity, reducing the need for frequent repairs and replacements.

The economic impact of fluid transport failure in industrial operations is significant, leading to downtime, increased maintenance costs, and potential losses in productivity. RTP, with its ability to resist chemical corrosion and pressure, helps mitigate these risks, offering a more reliable and cost-effective solution for industries relying on fluid transport systems.

When comparing RTP to traditional piping materials such as PVC or steel, RTP stands out in terms of durability and cost-effectiveness. While RTP pipes may have a higher upfront cost, their extended lifespan and reduced maintenance requirements lead to lower total ownership costs. For agricultural systems that are subject to frequent pressure changes and exposure to aggressive fertilizers, RTP provides a more reliable solution, ultimately lowering long-term operational costs.

Traditional pipes, such as PVC, tend to degrade faster when exposed to harsh environmental conditions. RTP, with its resistance to UV rays, corrosion, and pressure, ensures fewer replacements and less downtime. This makes RTP an excellent investment for large-scale agricultural systems looking for reliable and sustainable solutions.

Property | RTP | PVC | Metal |

Durability | High | Moderate | Moderate |

Corrosion Resistance | Excellent | Low | Poor |

Lifespan | Long (25-50 years) | Medium (10-20 years) | Short (5-10 years) |

Maintenance Cost | Low | Moderate | High |

RTP pipes contribute to sustainability by reducing water wastage. Their leak-proof design ensures that water transported through irrigation systems stays in the pipes rather than leaking into the environment. Furthermore, RTP can play a role in water reuse systems, allowing agricultural operations to recycle water for irrigation or fertilizer application.

The environmental benefits of using RTP in agriculture not only contribute to sustainability but also translate into economic savings. Less water wastage means lower water bills, and a more efficient irrigation system means better crop yields with lower resource input.

A large-scale irrigation project in California utilized RTP to transport water over long distances. The project faced challenges with water leakage and pipe deterioration when using traditional materials. After switching to RTP, the system experienced fewer leaks, reduced downtime, and less maintenance, leading to significant cost savings. Additionally, RTP’s flexibility and ease of installation contributed to faster project completion and fewer disruptions.

Application | Benefit of Using RTP | Economic Impact |

Irrigation Systems | Reduces leakage, enhances fluid transport | Low maintenance costs, long-term savings |

Fertilizer Transport | Corrosion resistance improves reliability | Reduced downtime, lower operational costs |

In industries such as chemical manufacturing, oil and gas, and food processing, fluid transport systems are critical for daily operations. RTP’s ability to handle high-pressure, corrosive, and high-temperature fluids makes it a top choice for these sectors. Whether it’s moving chemicals in a refinery or transporting edible oils in food production, RTP offers the durability and performance needed to keep operations running smoothly.

The cost savings in industrial applications come from RTP’s extended lifespan and reduced maintenance needs. Industries often face high costs due to pipe corrosion or leakage, which can lead to production downtime. RTP minimizes these risks, offering a more dependable and cost-efficient alternative to traditional materials.

When comparing RTP to traditional materials like steel or PVC, the advantages are clear. RTP is more resistant to corrosion, which is a critical factor when transporting chemicals or other harsh substances. Steel, although durable, is prone to rust and requires frequent maintenance. PVC, while cost-effective initially, can degrade over time, especially when exposed to chemicals or extreme temperatures.

The cost of maintaining and replacing traditional pipes can add up over time, making RTP a more economical option in the long run. With its enhanced durability and resistance to corrosion, RTP reduces the frequency of repairs and replacements, saving industrial operations significant amounts of money.

A chemical plant in Texas faced significant maintenance costs due to the constant corrosion of their metal pipes. After switching to RTP, the plant saw a dramatic reduction in downtime and maintenance costs. RTP’s resistance to the chemicals used in the plant’s processes allowed the system to operate without frequent repairs, leading to substantial savings in labor and materials.

While RTP systems may require a higher initial investment compared to traditional piping materials, their total cost of ownership (TCO) is considerably lower over the lifespan of the system. RTP’s durability, reduced maintenance needs, and energy efficiency all contribute to lower long-term costs.

By extending the lifespan of fluid transport systems and reducing downtime, RTP systems offer a cost-effective solution in both agricultural and industrial applications. The TCO savings are particularly significant in large-scale projects, where the volume of fluids transported is high, and operational efficiency is critical.

Material | Initial Cost | Maintenance Cost | Lifespan | Total Cost of Ownership |

RTP | High | Low | 25-50 years | Low |

PVC | Medium | Moderate | 10-20 years | Medium |

Metal | Low | High | 5-10 years | High |

One of the key benefits of RTP systems is their ability to reduce downtime and maintenance costs. Traditional pipes require frequent inspections, repairs, and replacements, all of which contribute to operational downtime and lost productivity. RTP’s resistance to wear and corrosion means that these pipes last longer and need fewer repairs, resulting in fewer interruptions to operations.

For agricultural operations, this means that irrigation systems can function more efficiently, ensuring that crops receive consistent watering without delays. In industrial settings, reduced downtime translates to more continuous production and fewer operational setbacks.

RTP systems are highly adaptable and scalable, making them suitable for both small-scale and large-scale applications. Whether you’re installing an irrigation system for a small farm or a complex fluid transport network for an industrial plant, RTP provides a flexible solution that can be customized to meet the specific needs of the project.

The ease of installation and flexibility of RTP systems make them an attractive option for projects of any size, ensuring that businesses in both agriculture and industry can scale their operations effectively without worrying about the limitations of traditional piping materials.

While the initial cost of RTP may be higher than traditional materials, it’s important to consider the long-term savings. Over the lifespan of the system, the reduced maintenance, longer lifespan, and lower risk of leaks or corrosion can result in significant cost savings.

Investing in RTP now can prevent future costs associated with pipe replacements, repairs, and downtime, making it a smart choice for businesses looking to save money over time.

Despite its many benefits, RTP adoption in some markets can be hindered by a lack of awareness, higher upfront costs, and resistance to change. Some agricultural and industrial businesses may be hesitant to switch from traditional piping materials due to the perceived complexity or higher initial costs.

However, as more businesses experience the long-term cost savings and benefits of RTP, adoption rates are likely to increase. Education, case studies, and data on the economic advantages of RTP will help overcome these barriers.

Reinforced Thermoplastic Pipes (RTP) provide substantial economic benefits in agricultural and industrial fluid systems. Their durability, corrosion resistance, and cost-effectiveness make them a smart investment. While RTP requires a higher initial cost, long-term savings in maintenance and operational efficiency justify the expense. As industries and agriculture move towards more sustainable solutions, RTP technology will evolve to meet growing demands. Companies like Anhui United Pipeline Co., Ltd. are leading the way, offering RTP systems that ensure reliable and cost-effective fluid management across sectors.

A: Reinforced Thermoplastic Pipes (RTP) are durable, corrosion-resistant pipes used for fluid transport in agricultural and industrial systems. They are ideal for applications requiring high strength and resistance to extreme temperatures.

A: RTP offers greater durability, corrosion resistance, and cost-effectiveness compared to traditional materials like metal and PVC. Their long lifespan reduces maintenance costs, making them a smart investment.

A: RTP reduces operational costs by minimizing maintenance and downtime in irrigation and fertilizer systems. Their durability ensures long-term savings, making them a cost-effective choice for agricultural fluid transport.

A: RTP is used in industries like chemical processing, oil & gas, and food processing. Their resistance to corrosion and high pressure makes them ideal for transporting chemicals and other industrial fluids, leading to reduced downtime and maintenance.

A: Yes, RTP helps in reducing water wastage by minimizing leakage in agricultural systems. Their sustainable design also contributes to long-term environmental savings, especially in water-intensive industries.