Views: 0 Author: Site Editor Publish Time: 2025-08-12 Origin: Site

Reinforced thermoplastic pipe, or rtp, is a strong, flexible pipe you can use for moving liquids safely. You often see rtp in oil and gas, mining, and city water systems. It stands out because it resists rust and handles high pressure. The global rtp market keeps growing. Look at the table below to see its value and growth:

Aspect | Details |

|---|---|

Market Size 2024 | USD 1.32 Billion |

Projected Market Size 2032 | USD 2.92 Billion |

CAGR (2026-2032) | 10.2% |

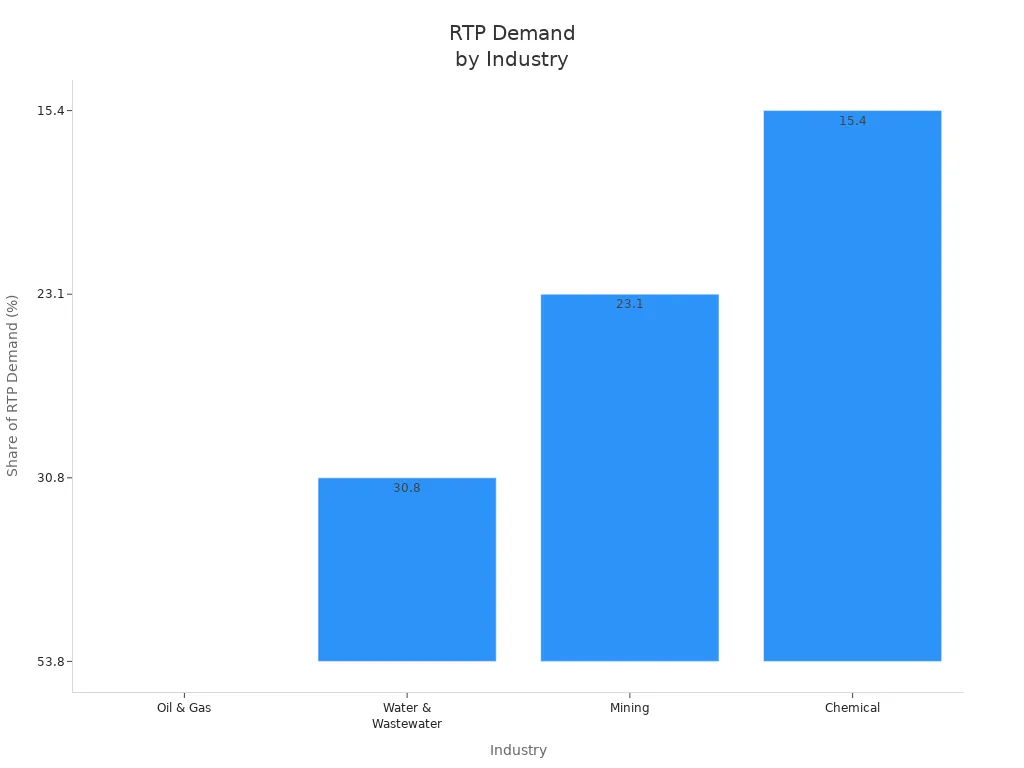

You can see how different industries use rtp in this chart:

Reinforced thermoplastic pipe is very strong and bends easily. It does not rust, so it works well for oil, gas, mining, and water systems. RTP has three main layers. The inside liner keeps out chemicals. The middle layer is strong and gives support. The outside jacket protects from weather. RTP uses different strong materials like aramid fiber and steel wire. These make RTP very strong and able to handle high pressure up to 90 bar. RTP lasts longer than steel pipes. It needs less fixing and is easier to put in place. It is lighter and bends more easily. You can trust RTP for hard jobs in rough places. It saves money by needing fewer repairs and less time to install.

When you look at rtp, you see it has many layers. Each layer does something important. This design lets rtp work well in oil, gas, mining, and water systems. Unitedpipe uses special materials so each layer lasts a long time.

Here is a table that shows the main layers, what they do, and the materials you often find in a reinforced thermoplastic pipe:

Layer | Role | Common Materials Used |

|---|---|---|

Internal thermoplastic liner | Protects from fluid corrosion and wear | PE100, PE-RT II, PE-X, PA, PPS, PVDF |

Reinforcement layer | Gives strength and stiffness | Polyester fiber, steel wire, aramid, glass fiber |

External thermoplastic jacket | Shields from sunlight, weather, and damage | UV-stabilized HDPE, PE-RT II |

Think of rtp like a sandwich. The inner liner touches the liquid and keeps it inside. The middle layer is strong and gives the pipe its power. The outer layer protects the pipe from sun, rain, and bumps.

The inner liner uses PE100, PE-RT II, PE-X, PA, PPS, and PVDF. These materials help the pipe fight chemicals and stop leaks. They keep the liquid safe inside.

The reinforcement layer is in the middle. It uses strong tapes or fibers. Unitedpipe uses polyester fiber, steel wire, aramid fiber, and glass fiber. This layer lets rtp handle heavy loads and high pressure.

The outer jacket uses UV-stabilized HDPE or PE-RT II. It keeps the pipe safe from sunlight and bad weather. This layer helps rtp last longer outside.

Unitedpipe makes sure every layer sticks well to the next. They use heat and pressure to join the layers together. This stops the layers from coming apart and keeps the pipe strong. Their factory uses smart machines and tough tests. Every batch gets checked for leaks, strength, and quality. This means you get a reinforced thermoplastic pipe you can trust.

Tip: The liner material you pick changes how rtp handles chemicals, heat, and pressure. For example, PVDF liners block gases like methane and carbon dioxide. PE100 and PA liners are good at fighting chemicals.

The middle layer of rtp is where the real strength comes from. Unitedpipe uses different types of reinforcement for different jobs. Each type has its own good points.

Here is a quick look at the main reinforcement types and what they offer:

Reinforcement Tape Type | Key Properties and Uses |

|---|---|

Aramid Fiber Tape | Very high strength, flexible, resists corrosion, used in offshore oil and gas pipelines |

Steel Wire Tape | Handles high pressure, strong, resists corrosion, good for harsh environments |

Polyester Fiber Tape | Durable, flexible, resists pressure, used in many industrial settings |

Glass Fiber Tape | Adds strength and stiffness, used for general reinforcement |

Aramid fiber tape gives rtp lots of strength and flexibility. You find it in pipes for oil and gas platforms in the ocean. It stands up to high pressure and hard jobs.

Steel wire tape makes rtp strong against pressure and damage. It works well in places like mines or power plants.

Polyester fiber tape gives a good mix of strength and flexibility. It helps rtp last longer and handle daily use.

Glass fiber tape adds stiffness and helps the pipe keep its shape.

Unitedpipe picks the right reinforcement for each job. They wrap the fibers or tapes around the pipe at special angles. This spreads out the force and keeps the pipe from breaking or bending. The result is a thermoplastic composite pipe that stays strong, even in tough jobs.

You can trust rtp from Unitedpipe because they test every pipe for leaks, pressure, and strength. Their checks make sure you get a pipe that works well and lasts a long time.

You might wonder how rtp can handle tough jobs. The secret is in the strong reinforcement layer. This layer uses fibers like aramid, glass, or polyester. They wrap around the pipe in a spiral pattern. You get a pipe that stands up to heavy loads and high-pressure applications. The fibers give rtp a high strength-to-weight ratio. You can use rtp instead of steel pipes in many places. It stays flexible and resists rust, unlike metal pipes.

The reinforcement layer sits between the inner liner and the outer jacket. It carries the pressure from inside the pipe. You get a sturdy pipe that does not bend or break easily. Non-reinforced pipes cannot handle the same pressure. For example, rtp can reach pressure ratings from 30 to 90 bar (3 to 9 MPa). Some types, like steel wire reinforced rtp, go even higher. You can trust rtp for high-pressure applications in oil and gas, mining, and water systems.

Here is a table showing how rtp compares to non-reinforced pipes:

Feature | RTP (Reinforced) | Non-Reinforced Thermoplastic Pipe |

|---|---|---|

Pressure Rating | Up to 90 bar (9 MPa) | Up to 10 bar (1 MPa) |

Flexibility | High | Moderate |

Corrosion Resistance | Excellent | Good |

Use in High-Pressure Applications | Yes | No |

Note: The spiral-wound, heat-bonded reinforcement makes rtp strong and reliable for high-pressure applications.

You need rtp to work in places where chemicals, heat, and pressure are a problem. The multi-layer design helps rtp resist corrosion and wear. It works in temperatures from -40°C to 110°C. You can use rtp for moving oil, gas, and chemicals. It does not need extra coatings to fight rust. The pipe’s flexibility makes it easy to install in rough terrain.

RTP uses advanced resins like PVDF and PTFE. These materials block harsh chemicals and keep the pipe stable in hot or cold conditions. The strong fibers in the reinforcement layer help rtp handle thermal cycling and mechanical stress. You get a pipe that lasts longer and needs less maintenance.

Unitedpipe tests every rtp to make sure it meets strict standards. Their pipes pass API 15S and DNV certifications. These tests check for leaks, strength, and safety. You get a pipe you can trust in the toughest jobs.

When you choose rtp, you get a safe, strong, and reliable solution for high-pressure applications in harsh environments.

If you pick rtp, you get a pipe that works well in hard places. It is very tough and does not rust. You do not need to worry about chemicals hurting the pipe. The pipe has many layers that keep it safe from bad liquids and dirt. The inside liner stops chemicals, and the outside jacket keeps out sun and rain.

Pipe Material | Estimated Lifespan | Key Characteristics and Maintenance Notes |

|---|---|---|

RTP (HDPE) | 50 to 100 years | High corrosion resistance, flexible, needs checks for joint integrity. |

Steel (Galvanized) | 40 to 70+ years | Prone to corrosion without coatings, needs regular maintenance. |

RTP lasts longer than steel pipes in most places. You do not need to add coatings or special chemicals. This saves you money and time. RTP fights rust better than steel pipes. It is a good choice for oil, gas, and water systems.

RTP does not rust like steel pipes.

The thermoplastic liner keeps out seawater and acid dirt.

You do not need to use harmful coatings.

Corrosion resistance helps the pipe last longer.

RTP needs less fixing and checking, so you save money and time.

RTP is strong and also bends easily. This makes putting it in place fast and simple. You can move the pipe around things that are in the way. This helps you finish jobs faster and with less work.

RTP is lighter than steel, so you use less gear.

You can put down up to 10 km of rtp each day. Steel pipes only reach about 2 km.

The spoolable design lets you use long pieces, so there are fewer joints and leaks.

RTP does not need repairs as often because it resists rust.

RTP helps you spend less money overall. It may cost more at first, but you pay less for workers, tools, and fixing problems. Over time, rtp saves you money compared to steel pipes. You get a pipe that lasts longer and keeps your system working well.

Oil and gas pipelines are found in many places. They move oil and gas from wells to plants. Some pipelines are on land, and some are in shallow water. These pipes help carry fluids for oil recovery. They also move wastewater safely. Old steel pipelines sometimes need fixing. You can put RTP liners inside to stop rust.

Here are some main uses for oil and gas pipelines:

Onshore gathering lines take oil and gas from wells to buildings.

Offshore production lines work under the sea and fight saltwater.

Injection and disposal lines send fluids for recovery and move wastewater.

Pipeline rehabilitation uses RTP liners to protect old steel pipes.

RTP lets you work faster and safer. It does not rust and can handle high pressure. You can use it for moving strong fluids. It is also good for fixing pipelines without stopping the flow.

Tip: Using RTP in oil and gas pipelines gives you real-time monitoring. Smart sensors and data tools help you find problems early.

Some jobs in oil and gas need special pipes. Unitedpipe makes flexible RTP for coal mines, power plants, and rescue work. These pipes handle high pressure, heat, and tough chemicals. They last longer than steel pipes and need less fixing.

RTP is great for mining and minerals. It is light, bends easily, and does not wear out fast. You can use it for moving slurry and tailings. It works better than steel pipes because it fights rust and damage. You save money on repairs and downtime.

Application Area | Why RTP Works Well |

|---|---|

Handles rough slurries, resists chemicals | |

Power Plants | Moves coal slurry, stands up to high heat |

Emergency Rescue | Flexible, quick to install, reliable in emergencies |

Municipal Engineering | Safe for water, resists rust and leaks |

You can use RTP in oil and gas pipelines on land and in shallow water. It works well in places up to 30 meters deep. Unitedpipe’s advanced products give you strong and safe pipelines for many needs.

You have learned that reinforced thermoplastic pipe is strong and bends easily. It does not rust and works well in many jobs. The pipe uses special layers and new materials to last longer. It can handle hard places and tough work. Some new ideas for RTP are:

Materials that are light and better for the planet

Systems that watch the pipe and keep it safe all the time

Ways to put the pipe in quickly and without problems

You can pick RTP for oil, gas, mining, or water work. If you want a pipeline that fits your job, talk to Unitedpipe for help and special plans. RTP will make future pipelines safer and better for the earth.

Reinforced thermoplastic pipe is much lighter than steel. It bends without breaking. It does not rust or get damaged by chemicals. This pipe lasts longer in tough places. You can put it in faster than steel pipe. It is good for oil and gas pipelines. It also works for other jobs with high pressure.

Yes, you can use rtp for high-pressure jobs. It stays strong in oil and gas pipelines. Many people use it in this field. It lasts a long time and does not rust easily.

RTP has special liners and jackets. These layers stop water, chemicals, and dirt from getting in. You do not need to add extra coatings. The pipe stays strong and lasts long, even where steel would rust.

You can use thermoplastic composite pipe in many places. It works in oil and gas pipelines, mining, water systems, and city projects. It moves liquids, slurries, and chemicals. You can use it for new jobs or to fix old pipes.

Reinforced thermoplastic pipe can last 50 to 100 years. It keeps its strength and does not rust over time. You spend less money fixing it. You get a pipe you can trust.